by Andy Pace, European Sales Manager

When manufacturers look to speed up assembly processes, the first instinct is often to optimize existing methods-running impact drivers faster, shortening weld times, or reducing fastener counts. While these incremental improvements help, the most significant gains come from rethinking your joining method entirely and switching to adhesives.

The adhesive advantage is simple: Assembly becomes as straightforward as applying adhesive to one component, bringing the second component into position, and you’re done. Fewer steps, no hardware to track or inventory, and just one tool to master.

Once you’re ready to explore adhesives, choosing the right technology is critical for maximizing speed gains. Many manufacturers are familiar with epoxy’s strength and polyurethane’s flexibility, but fewer know about methyl methacrylate adhesives (MMAs)-which deliver an optimal balance of both properties while excelling at accelerating assembly operations.

Understanding Adhesive Timing

Since we’re focused on cycle times, here’s how we define the key timing parameters for adhesives:

|

Timing Parameter |

Definition |

Typical MMA Range |

|

Working Time |

How long the adhesive remains workable and parts should be joined before beginning to cure |

1-3 minutes to 100+ minutes |

|

Fixture Time |

Time to reach enough strength for parts to have enough green strength and be moved. |

6-8 minutes to 180-210 minutes |

|

Full Cure |

Time to achieve 100% bond strength |

Approximately 24 hours |

The beauty of MMAs lies in their proven track record-these formulations have delivered reliable performance for decades. Even better, these critical timing parameters can be easily customized through special formulations to match your specific production requirements.

Additional Productivity Benefits

SCIGRIP Adhesives® deliver several advantages that compound your cycle time savings:

- Reduced surface preparation: Most applications can use MMA adhesives without extensive surface prep. Only surface cleaning is required.

- Versatile bonding: Many MMA formulations can bond multiple different materials within the same assembly

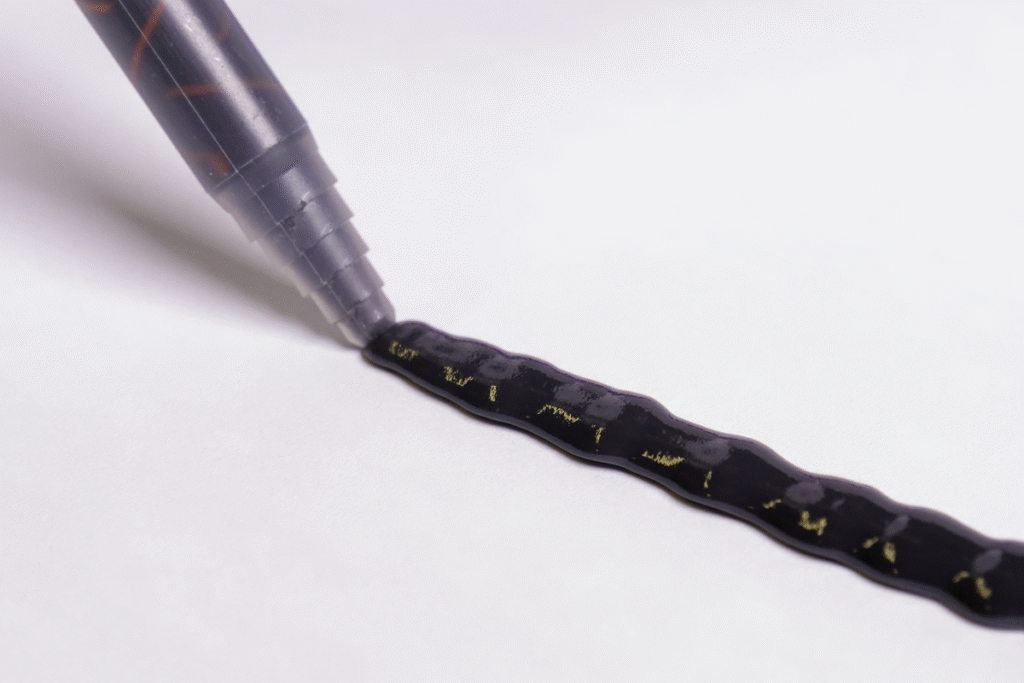

- Streamlined application: Available in convenient cartridge systems for accurate mix ratios or bulk dispensing for high-volume applications

Don’t overlook your application process. For high-volume production, automated bulk dispensing systems maximize speed and consistency. For smaller volumes or varied assemblies, manual cartridge systems offer convenience and precision. With today’s robotic technology, fully automated adhesive application can further slash cycle times while ensuring consistent quality.

Ready to increase your build productivity? See how SCIGRIP improved cycle times for a tank manufacturer: CaseStudy-SG400LSE TankRepair 040924x.pdf