by Jeff McCann – National Sales Manager SCIGRIP/Arjay

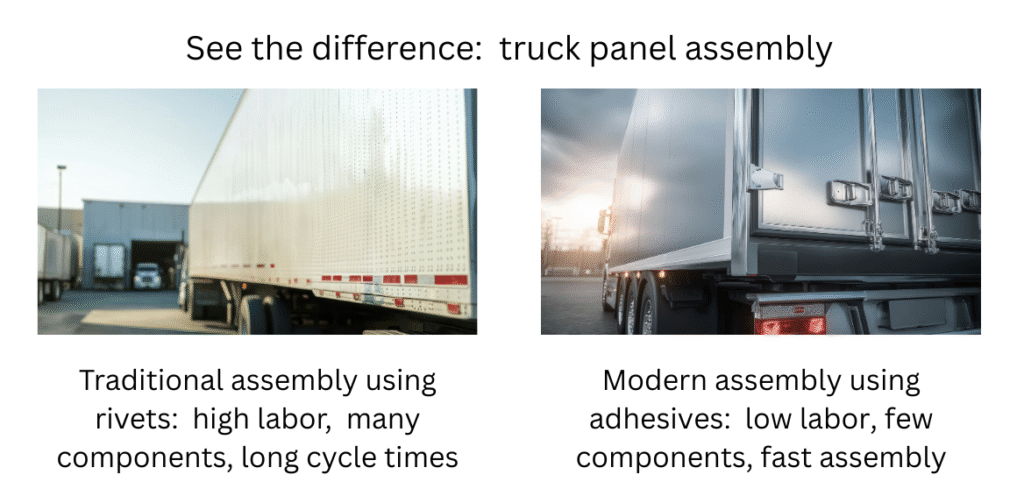

Replace fasteners and welding. Reduce costs. Simplify production.

In today’s competitive manufacturing environment, every cost reduction matters-and the biggest savings often come from eliminating entire process steps rather than just optimizing existing ones. MMA adhesives can dramatically lower your fabrication costs by replacing traditional fasteners and welding with a simpler, more efficient bonding solution.

The Hidden Costs of Traditional Assembly Methods

Most manufacturers focus on the obvious costs-material prices, labor hours, equipment depreciation. But fasteners and welding carry hidden expenses that quickly add up:

• Skilled labor requirements: Welding demands certified operators and ongoing training

• Surface preparation: Extensive cleaning, grinding, and prep work

• Finishing operations: Sanding, grinding, polishing, and coating over welds

• Manufacturing complexity: Drilling holes, creating cut-outs, precise alignment

• Inventory burden: Stocking multiple fastener types, sizes, and grades

• Quality control: Inspection requirements for welds and torque specifications

How SCIGRIP Reduces Your Fabrication Costs

Basic skilled labor is all you need. MMA cartridge-based systems are designed for easy application by any production worker-no specialized certifications required. This flexibility dramatically expands your available labor pool while reducing training time and costs.

Minimal surface preparation required. Most MMA applications can proceed without extensive surface prep, eliminating time-consuming cleaning and abrasive processes that slow production and consume materials.

Remove entire manufacturing steps. Adhesives require no holes, cut-outs, or complex fixtures. This simplification reduces machining time, eliminates secondary operations, and decreases the chance for dimensional errors.

Minimal finishing work needed. In most applications, MMA adhesive bonds require no sanding, scraping, or polishing. The clean application creates smooth, aesthetically pleasing joints right from the start.

Real-World Cost Benefits

Consider a typical assembly operation switching from mechanical fasteners to MMA adhesives:

• Labor reduction: Eliminate time spent locating, counting, and installing multiple fasteners

• Tool simplification: Replace multiple specialized tools with simple dispensing equipment

• Inventory optimization: Reduce fastener SKUs and associated storage costs

• Quality improvements: Fewer potential failure points mean reduced rework and warranty

claims

• Faster throughput: Streamlined process enables higher production volumes

The Efficiency Multiplier Effect

Cost reduction through adhesives creates a multiplier effect throughout your operation. Faster assembly times mean higher throughput. Simplified processes reduce training requirements. Fewer quality issues decrease customer service demands. The result is a leaner, more profitable operation that can respond quickly to market demands.

Ready to lower your fabrication costs? Discover how other manufacturers have achieved significant savings: Case Studies — SCIGRIP Structural Adhesives

Ready to lower your fabrication costs? Discover how other manufacturers have achieved significant savings: Case Studies — SCIGRIP Structural Adhesives