by Allen Hughes – Health, Safety and Environment Lead

Safer manufacturing starts here.

Workplace safety isn’t just about compliance-it’s about protecting your most valuable assets: your people. Every day, manufacturing workers face hazards from traditional assembly methods that simply don’t exist with modern adhesive technology. MMA adhesives can significantly improve workplace safety while maintaining the high-performance bonds your applications demand.

The Safety Advantages of SCIGRIP

Styrene-free formulation means no negative health effects. Unlike many competitive adhesives, leading MMA formulations contain no styrene, eliminating concerns about vapor exposure and associated health risks. Workers can apply these adhesives with confidence, knowing they’re not being exposed to harmful chemicals.

Eliminate hand and finger injuries. Manual handling of fasteners, drilling operations, and tool related injuries are leading causes of workplace accidents in manufacturing. Adhesive application eliminates these mechanical hazard sources entirely. No more cuts from sharp edges, pinched fingers from power tools, or repetitive strain injuries from fastener installation.

No restricted area requirements. Unlike welding operations that require safety zones, special ventilation, fire watch procedures, and restricted access, MMA adhesives can be applied safely in normal manufacturing environments without cordoning off work areas or disrupting adjacent operations.

Welding Hazards Eliminated

Traditional welding presents multiple safety challenges:

- Electrical shock hazards from high-voltage equipment

- Arc flash and burn risks from intense heat and light

- Fume exposure requiring expensive ventilation systems

- Fire and explosion risks from sparks and hot materials

- Eye and skin damage from UV radiation exposure

MMA adhesives eliminate all of these risks while delivering comparable or superior joint strength.

Simplified Safety Training and Compliance

Reduced training requirements mean faster onboarding and lower ongoing education costs. Instead of extensive welding certifications, safety protocols, and equipment training, workers need only basic adhesive handling instruction.

Simplified PPE requirements reduce equipment costs and improve worker compliance. No specialized welding helmets, heat-resistant gloves, or fire-retardant clothing-standard safety glasses and nitrile gloves provide adequate protection for most MMA adhesive applications.

Lower insurance costs often result from demonstrably safer manufacturing processes. Many insurers recognize the risk reduction achieved by eliminating welding and reducing mechanical assembly hazards.

Environmental Health Benefits

Beyond immediate physical safety, SCIGRIP contributes to better long-term health outcomes:

- No metal fume exposure like welding generates

- Minimal volatile organic compounds (VOCs) compared to solvent-based alternatives

- No ozone depletion from UV-intensive welding processes

- Reduced noise exposure from power tools and pneumatic equipment

Creating a Safety Culture

When you demonstrate commitment to worker safety through technology choices, you create a culture where safety becomes everyone’s priority. Workers appreciate employers who invest in safer alternatives rather than simply managing existing hazards.

Emergency Response Simplification

Adhesive-based assembly operations have simpler emergency response requirements:

- No fire suppression systems designed for welding operations

- Reduced first aid complexity without burn treatment protocols

Simplified evacuation procedures without electrical or explosion hazards

Ready to enhance workplace safety? See our safe bonding procedures in action:

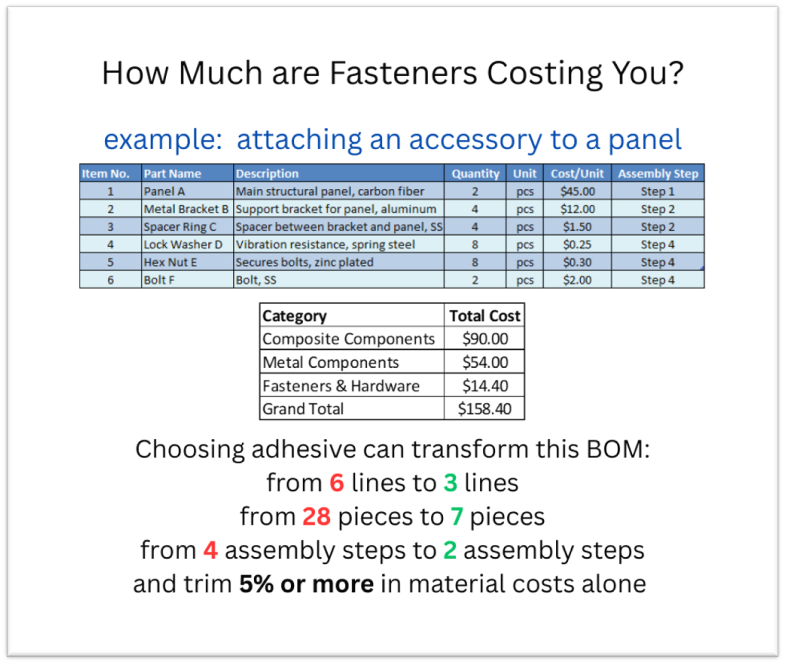

Ready to simplify your BOMs? See how other manufacturers have streamlined their materials management: Case Studies — SCIGRIP Structural Adhesives