by Ricardo Hernan – Business Development Manager

Fewer parts. Greater versatility. Streamlined inventory.

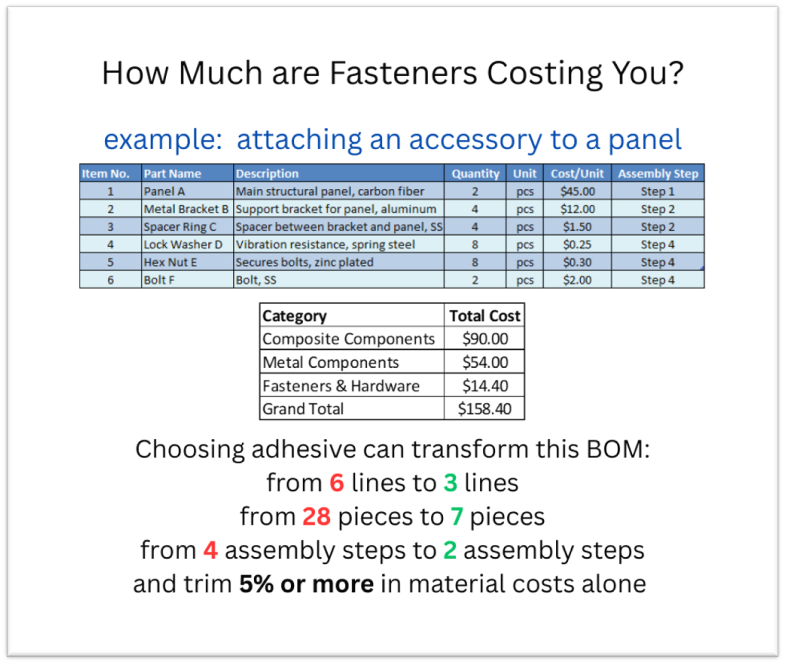

Every manufacturing engineer knows the frustration: Bill of Materials (BOMs) that seem to grow longer with each design iteration, inventory systems bursting with fastener variations, and purchasing departments juggling hundreds of small-value SKUs. MMA Adhesives offer an elegant solution-dramatically simplifying your BOMs while improving assembly performance.

The BOM Complexity Problem

Traditional assembly methods create BOM bloat:

- Fastener proliferation: Different sizes, materials, and coatings for various applications

- Hardware multiplication: Washers, nuts, bolts, rivets, and specialty fasteners

- Surface preparation products: Cleaning agents, primers, abrasives for welding prep

- Finishing materials: Grinding wheels, polishing compounds, protective coatings

- Quality control items: Torque specifications, thread-locking compounds, inspection tools

Each line item adds purchasing complexity, inventory carrying costs, and potential supply chain disruption points.

How SCIGRIP Simplifies Your Materials Management

Reduce inventory parts dramatically. Eliminate threaded fasteners, rivets, washers, and associated hardware. A single MMA adhesive can replace dozens of mechanical fastener SKUs across multiple assemblies.

Versatile across applications. Many MMA formulations can bond multiple different materials within the same assembly-aluminum to composite, steel to plastic, dissimilar metals together. This versatility means one adhesive replaces multiple joining solutions.

Minimal surface preparation required. Some applications typically requirecleaning agents, primers, or abrasion. MMA adhesives are designed to bond effectively to substrates with minimal prep, potentially eliminating entire categories of preparatory materials from your BOM.

The Purchasing Department Will Thank You

Consider the administrative burden reduction:

- Fewer supplier relationships to manage and qualify

- Consolidated purchasing power through volume concentration

- Simplified inventory management with fewer SKUs to track

- Reduced obsolescence risk from fastener specification changes

- Streamlined quality control with fewer incoming inspection requirements

Design Flexibility Benefits

Simplified BOMs enable design agility. When you’re not constrained by fastener availability or welding access requirements, engineers gain freedom to optimize designs for performance rather than manufacturing limitations. This flexibility accelerates product development cycles and enables rapid response to customer requirements.

Inventory Carrying Cost Reduction

The value is clear: Replace 50+ fastener SKUs with 2-3 adhesive formulations, and your inventory carrying costs plummet. Lower inventory means:

- Reduced warehouse space requirements

- Decreased working capital tied up in inventory

- Simplified cycle counting and inventory audits

- Lower insurance and handling costs

Supply Chain Risk Mitigation

Fewer suppliers mean fewer potential disruption points. SCIGRIP’s global manufacturing presence and extensive distributor network provide supply security that scattered fastener suppliers simply cannot match.

Ready to simplify your BOMs? See how other manufacturers have streamlined their materials management: Case Studies — SCIGRIP Structural Adhesives